First week of Wageningen University’s module ‘Greenhouse Technology’ (FTE-31306) done, with this 2019-published book written by its three main lecturers. Would recommend! pic.twitter.com/q3nq9ujUoB

— Alex van Tuyll (@AlexVanTuyll) January 11, 2019

For the past month, I have been following one of Wageningen University’s flagship courses: Greenhouse Technology, given by Cecilia Stanghellini, Bert van ’t Ooster, and Ep Heuvelink. Last Thursday, we went on an excursion to three companies: Ter Laak Orchids, Ridder Growing Solutions, and Holstein Flowers.

Ter Laak Orchids

Our first stop was Ter Laak Orchids. Orchids are tricky to grow but beautiful. There’s plenty of money in this industry. Ter Laak is in the process of finishing their newest extension, a 5-hectare greenhouse costing 35 million euros (or 700 euros per square metre). In their 8-hectare greenhouse, Ter Laak employs 225 people, of which half are there full-time. That said, margins are low, as with most agricultural ventures. As a result, a lot is being automated.

The orchids are imported from laboratories in places as far flung as Taiwan. Once they are old enough, are placed in pots. These pots are transported on a clever system of conveyor belts built by WPS, and each have their own RFID chip, allowing for tracking. Sorting is also done automatically, with the pots going through a photo studio (really, that’s what it looks like) with 6 cameras. This gives Ter Laak plenty of insight during the 70 weeks needed to produce the final product. Being in a greenhouse full of orchids was an experience in itself, let alone having them moving around on conveyor belts above our heads. Not unlike Charlie and the Chocolate Factory.

Ter Laak’s greenhouses feature more than just automation. They also include energy-saving installations by Technokas, which allow for 50% in energy savings compared to the conventional equivalent greenhouse. One of these installations involves a series of black pipes hanging from the ceiling. Orchids have a lower light requirement than tomatoes or cucumbers – in fact, many ornamental crops are sensitive to excess sunlight. The glass in Ter Laak’s new greenhouse is convex, focusing incoming solar radiation onto these black pipes and heating water. To make best use of this, the pipes follow the sun throughout the day, as can be seen in this video:

Ridder Growing Solutions (formerly HortiMaX)

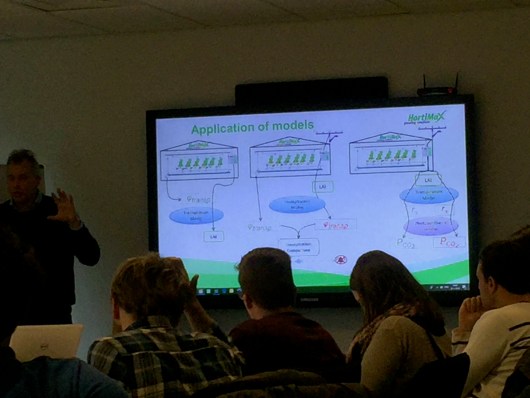

Ridder Growing Solutions have made a number of award-winning systems. Climate control and sensors make up around 2% of the total budget of most Dutch greenhouses, but they are crucial. Needless to say, visiting Ridder Growing Solutions was less visually remarkable than Ter Laak. Nevertheless, Ad de Koning, innovation manager, gave an enthusiastic presentation.

My main takeaway from Ad’s presentation was the usefulness of models. Models are used to some extent in Ridder’s systems, such as for some feed-forward control. Models are also good for things that can’t be measured. For example, transpiration can be measured in an experimental setup, but doing this in a commercial greenhouse is impractical. Ridder collaborated with people from Wageningen University, including Cecilia Stanghellini, to use models.

(Speaking of which – Ridder make systems for weighing substrate, which can be used to estimate the amount of water in the substrate. I used data from one of these systems in my BSc thesis. This too was from an experimental greenhouse, and would not be used in most greenhouses.)

However, models become more troublesome with increasing complexity. There are far too many parameters to be adjusted, and models can be sensitive to mistakes in these parameters. Ad highlighted how Ridder’s systems are designed to be easy to use.

The alternative to models is data. Lots of it. Ridder’s systems can sample thousands of variables every minute. This data can be used in machine learning algorithms, or uploaded to platforms like LetsGrow, to share data between growers.

Ridder’s conventional competitors are companies like Priva and Hoogendoorn. However, with data becoming increasingly important, smaller start-ups like Agrilyst and Motorleaf are becoming serious rivals as well.

Holstein Flowers

Our last stop was at Holstein Flowers’ Futura nursery. Holstein have been growing gerberas since 1946. It felt great to be inside a well-lit greenhouse on an otherwise gloomy winter’s day.

Holstein’s system has some automation, with carts full of flowers being pulled down the aisles autonomously. Other than that, though, gerberas are much trickier to automate. The challenge lies in picking, which is currently done by ripping the entire stem from the plant by hand. Though it looks savage, are two reasons why this is done:

- Cutting the stems breaks cells open, making the plants vulnerable to disease. Ripping the stems leaves cells intact.

- Longer stems are worth more, and leaving part of the stem behind also makes the plant more vulnerable to disease.

In case you haven’t noticed, gerberas are vulnerable to disease. No wonder we all had to get suited up before entering the greenhouse. Mathieu van Holstein told us how gerberas are susceptible to aphids, mildews, lice, and even mice (yes, the cats in those pictures have a practical purpose).

This is also one of the purposes of their climate control: to avoid condensation on the plants. They also use three different shading screens, to keep a consistent day length. They are one of the first gerbera growers in the Netherlands to be using LED lighting as well.

Many ornamental flowers are grown in parts of Africa. Luckily, gerberas are harder to transport than flowers like roses, which is one of the reasons why they are still being grown in the Netherlands. That said, it’s a tough industry. The current trend is to scale up or die. Only 20 companies are responsible for gerbera production in the Netherlands.

Closing remarks

All in all, it was a fascinating excursion in a fascinating industry. Ornamental plants may not be as useful as growing food, but – in the words of Oscar Wilde and Sir Roger Scruton – all art is useless, which is a good thing. Put usefulness first, and you will lose it. Put beauty first, and what you do will be useful forever.